Bottle-style freedom. Can-level cost. 100% recyclable aluminum.

Introducing ReLid

Swiss-engineered tooling, built and scaled in the USA. ReLid USA will run limited-market pilots in Q3–Q4 2025, giving brands a plug-and-play path to resealable cans—no plastic, no line slow-downs, no compromises.

Sustainability at Its Core:

We understand the importance of environmental responsibility.

ReLid promotes sustainability by reducing single-use plastic waste associated with traditional beverage packaging. By resealing and recycling, consumers contribute to a greener future.

Advanced Resealable Technology: Designed, developed and produced in Switzerland, ReLid will soon be manufactured in the Central USA.

Versatile Compatibility: Our innovative lid is designed to fit a wide range of beverage cans sizes and can be used for both carbonated and noncarbonated drinks. ReLid effortlessly adapts to all filling/seaming lines providing a true, universal drop-in solution.

Environmental Impact

Every ReLid makes a difference. Our 100% aluminum solution helps reduce plastic waste and promotes a circular economy through infinite recyclability.

U.S. can-alloy recycling rate backing ReLid's closed loop

Plastic closures ReLid can displace in Phase 1 ('25–'30)

Infinitely recyclable aluminum in every lid

Introducing ReLid is a milestone for our company. With production now underway in Europe and soon in the central US, we are providing a scalable, sustainable, packaging solution to the beverage industry," said Bill Brandell, founder at ReLid USA. "We are excited to offer consumers an infinitely recyclable solution that revolutionizes their beverage consumption experience.

Let's Work Together

ReLid USA is the Next Level in sustainable, value-added, infinitely recyclable, aluminum beverage can packaging.

SUPPORTING THE CIRCULAR ECONOMY

We build upon the inherent environmental advantages of recycling aluminum beverage cans. The ReLid "on top" provides the only 100% aluminum closure that Re-Seals after opening. YES, Spill-proof and retains carbonation. ReLid provides enhanced functionality for the on-the-go consumer while reducing plastic waste.

Why Bottlers Choose ReLid USA

- True drop-in – Runs on standard 202/206 seamers; zero adapters, zero speed loss.

- Universal profile – One lid covers 12 oz, 16 oz, 19.2 oz; still, carbonated, hot-fill or pasteurized.

- Modular scale – Each "Quad" adds ~55 M lids/yr; capacity grows only when demand does.

Why Mobile Consumers Care

On-the-go drinkers finally get a can that closes. ReLid stays spill-proof and keeps carbonation all day—commuters, festival-goers, and parents can open, sip, click, repeat without switching back to bottles. Early Tier-1 trials show portability lifts repeat-purchase intent.

Sustainability at its Core

On the go Resealability

Its real and a drop-in for Bottlers

This!

Why?

A Greener future demands resealable 100% aluminum lids for canned drinks!

Let's start delivering the ReLid Solution…today!

Ready to scale!

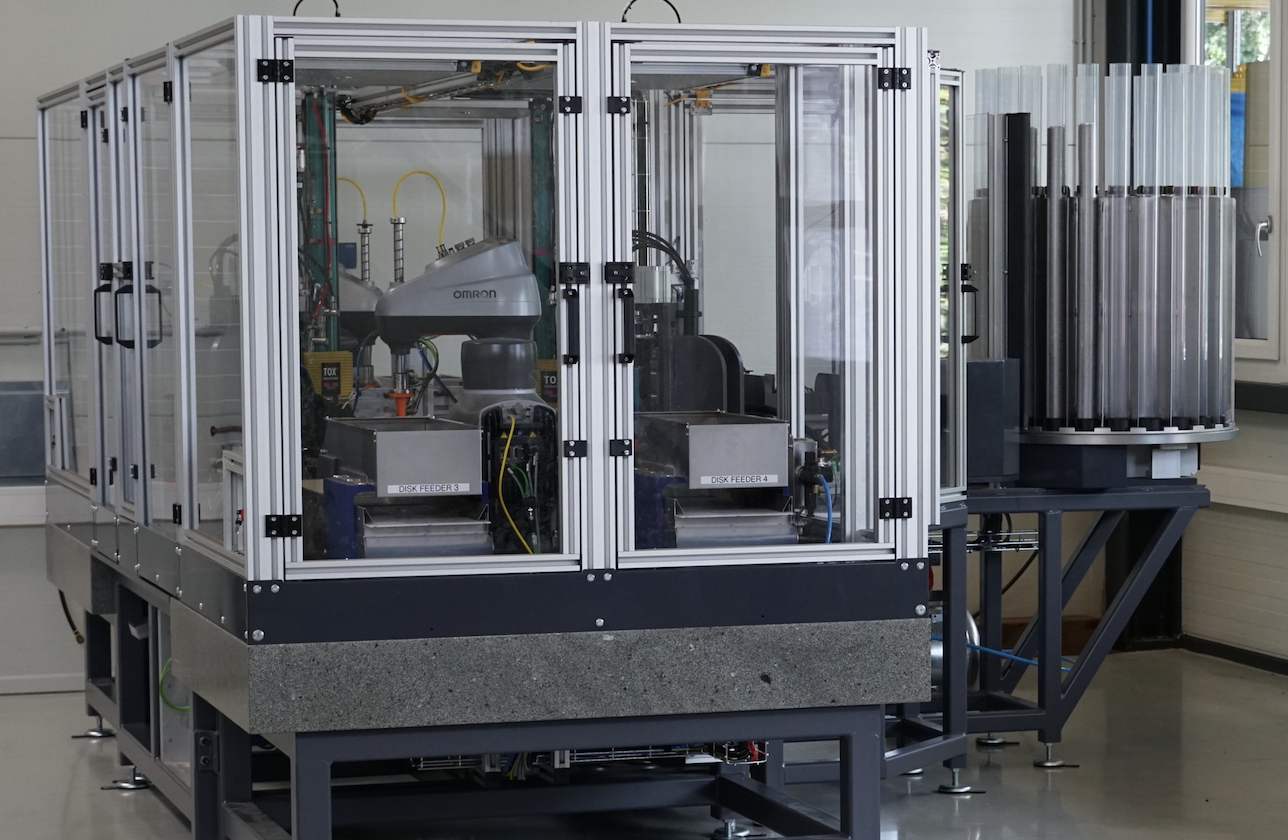

We have partnered with Leuthold Mechanik AG, more popularly known as HLM. HLM has 50 years of experience in the manufacture of machine systems for the production of thin-walled aluminum packaging.

Companies go to HLM when they want to do something that is real and it will work 100% of the time… AND disrupt the market.

Now in Production

ReLid USA has designed, developed, and built the first modules for making the resealable ends. They work hand in hand with HLM and ReLid USA. We are working together to redefine the future of beverage packaging.

ReLid Vision

Designed and developed with Swiss commitment to quality and reliability

Designed and developed by an experienced Swiss engineering group with a commitment to sustainability

Designed and developed with a commitment to provide the ability to transition to large scale production rapidly

We think of innovation as not only something novel but something that also impacts the greater good. ReLid USA has assembled a team of experts in design, development, large scale manufacturing, and innovation commercialization that is committed to making a difference.

ReLid USA Journey

Our roadmap to revolutionizing the beverage packaging industry

Concept proven; provisional patents & pilot tooling ordered

ReLid USA incorporated; Illinois site secured; Swiss-engineered tooling shipped

Q3–Q4 pilots with two champion brands validate line speed & consumer appeal

Quad #1 online → initial capacity ≈ 55 M lids/yr

Quad #2 installed → cumulative capacity ≈ 110 M lids/yr

Linear #1 added → capacity ≈ 435 M lids/yr

Linear #2 added → capacity ≈ 870 M lids/yr

Linear #3 (partial year) pushes run rate toward 1.2B lids & $240M revenue

Founded by William (Bill) Brandell, a 20-year aluminum-packaging veteran, ReLid USA owns exclusive North-American rights to the patented resealable lid. While our tooling draws on precision Swiss engineering, every lid will be manufactured, tested, and shipped from Illinois to support American beverage lines and American jobs.

Frequently Asked Questions

Find answers to common questions about ReLid, our sustainable packaging solution for canned beverages.

Let's Work Together

Please provide some information on your project or goals and we'll move the conversation on from there.

Let's build the future of the can.

hello@relidusa.com | © 2025 ReLid USA